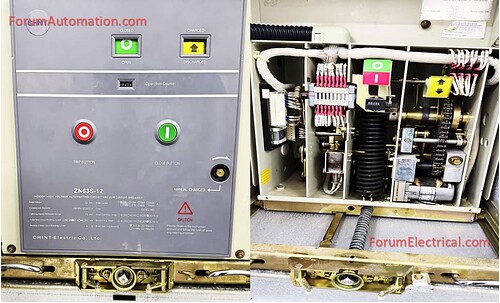

Corrective Maintenance Inspection of Vacuum Circuit Breaker (VCB) – Case Study

Several faults were discovered during a corrective maintenance (CM) inspection of a vacuum circuit breaker (VCB) highlighting the significance of thorough checks and stringent safety protocols.

The inspection discovered burning and damage to the solenoid coil which had a direct impact on the breaker’s operation as well as mechanical wear in the moving parts and springs.

Additionally,

- Dust accumulation &

- Carbon traces

were discovered within the mechanism.

To ensure safety the breaker was promptly isolated, tagged out and taken out of operation until the damaged solenoid coil and other spare parts might be replaced.

This case study illustrates the importance of rigorous inspection in identifying hidden defects prior to restoration as well as ensuring that preventative and corrective interventions work together to maintain the safety, dependability and long-term performance of the medium voltage (MV) electrical networks.

You can also follow us on AutomationForum.co, Facebook and Linkedin to receive daily Instrumentation updates.

You can also follow us on ForumElectrical.com , Facebook and Linkedin to receive daily Electrical updates.