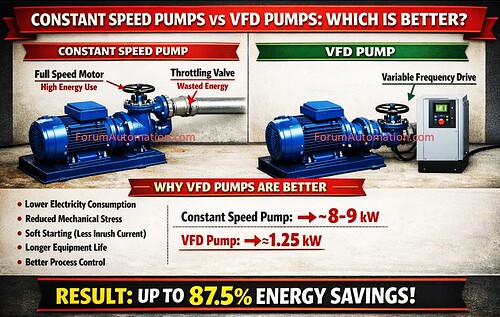

When comparing constant speed pumps and VFD (Variable Frequency Drive) pumps is the better option in most applications especially where the flow demand varies.

Why VFD pumps are better?

A constant speed pump always runs at full speed and flow control is done by throttling valves which wastes energy.

A VFD pump on the other end adjusts the motor speed to match the required flow making it far more energy efficient.

Advantages of VFD Pumps

1). Lower electricity consumption,

2). Reduced mechanical stress on pump and motor,

3). Soft starting (less inrush current),

4). Longer equipment life and

5). Better process control.

What happens to power when flow is reduced to half?

This is explained by the Affinity Laws for centrifugal pumps:

Flow (Q) ∝ Speed (N)

Head (H) ∝ Speed ²

Power (P) ∝ Speed ³

If flow is reduced to 50% the speed also reduces to about 50%.

So

Power = (0.5)³ = 0.125

Which means power consumption becomes 12.5% of original power

In other term energy savings of about 87.5%

For Example

If a pump consumes 10 kW at full flow:

At 50% flow with VFD → Power ≈ 1.25 kW

But with a constant speed pump even if you reduce flow using a valve the power consumption might only drop slightly (for example from 10 kW to 8-9 kW) because the motor still runs at full speed.

For systems where flow demand changes VFD pumps are significantly better and more energy efficient.

Reducing flow using a VFD drastically reduces power consumption while throttling in constant speed pumps wastes energy.

You can also follow us on AutomationForum.co, Facebook and Linkedin to receive daily Instrumentation updates.

You can also follow us on ForumElectrical.com , Facebook and Linkedin to receive daily Electrical updates.