Can PLC work without SCADA?

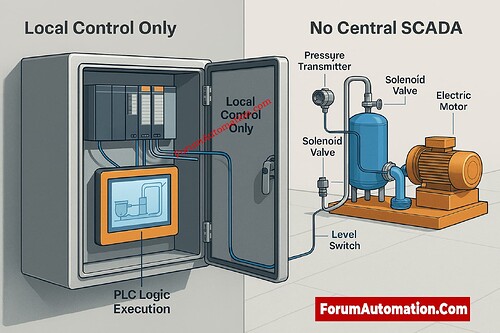

A Programmable Logic Controller (PLC) can run just fine without a SCADA (Supervisory Control and Data Acquisition) system. A PLC can control machines and processes on its own without SCADA software since it runs logic directly depending on inputs and outputs.

- Local Control Capability

PLCs are independent devices that can receive sensor inputs, run control logic, and turn on outputs to operate motors, actuators, and valves. This lets people work on their own for small or local systems without needing higher-level supervision.

- When SCADA is Not Required

The PLC may run the whole operation on its own in simple devices like conveyors, filling systems, or compressors. Operators can keep an eye on and control the system with local HMIs, pushbuttons, or indicator lights.

- What You Lose Without SCADA

Without SCADA, you can’t do things like log data, see trends, keep track of alarms, or monitor things from a central location. SCADA makes it easier to see, report, and diagnose problems across the whole plant, although it is not necessary for basic PLC operation.

- Practical Use Cases

PLC-only systems are widespread in industrial equipment that doesn’t need to connect to the internet in real time or that stands alone. Integrating SCADA makes it easier to keep an eye on and analyze data for big or multi-site businesses.

For minor automation tasks, a PLC can work without SCADA. However, SCADA is useful for central monitoring, trending, and analyzing historical data in bigger systems.