Can I Use a Normal Shielded Cable Instead of Thermocouple Extension Wire for Connecting a Thermocouple?

Can I Use a Normal Shielded Cable Instead of Thermocouple Extension Wire for Connecting a Thermocouple?

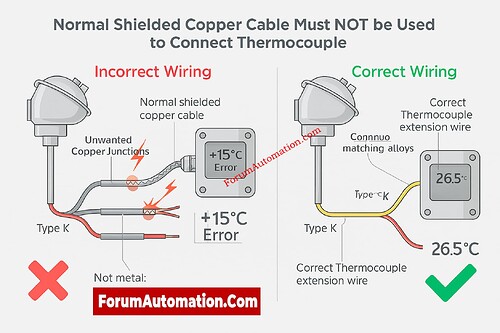

No, you shouldn’t use a regular shielded copper cable to connect or expand a thermocouple. You need to use thermocouple extension wire or thermocouple compensating cable that is the same kind as the thermocouple (K, J, T, N, etc.) to get an accurate temperature reading. The Seebeck effect is what makes a thermocouple work. It happens when two different metals create a millivolt signal based on temperature. If you put in any metal other than the thermocouple alloy, such ordinary copper conductors, you make more junctions that you didn’t mean to. Each junction makes its own thermoelectric voltage, which leads to big mistakes in readings. This can easily cause a difference of 10 to 20 degrees Celsius, especially over long wire runs or when the temperature changes.

Thermocouple extension cables are made from the same alloys or alloys that work well with each other. This keeps the temperature signal constant and accurate from the sensor head to the transmitter, PLC, or DCS.

What about shielding? Shielding only works for electrical noise from things like VFDs, motors, solenoids, contactors, and so on. But shielding can’t fix the thermoelectric mistakes that happen when you choose the wrong metals for the conductors. If the conductor is not TC-compatible, even a high-quality shielded instrumentation cable will still change the thermocouple signal.

Always connect the right thermocouple extension or compensating wire from end to end. Use shielding only when you think EMI/RFI noise will be present. To keep process applications from having big measurement errors and losing reliability, don’t use conventional shielded copper wire for thermocouple circuits.