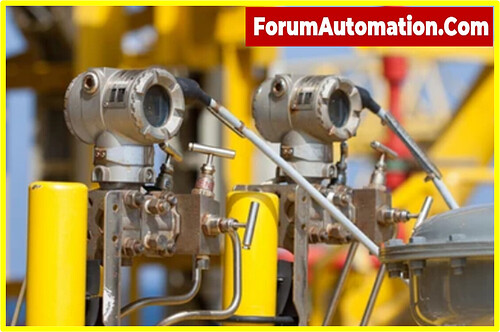

When an operator reports that the flow indication is higher than expected, a systematic approach to checking the issue can help identify the root cause and implement appropriate corrective measures. Here is a step-by-step process:

Step no.1 - Flushing the Transmitter

- Begin by flushing the flow transmitter.

- Flushing removes any debris or contaminants that may have accumulated within the transmitter, potentially affecting its accuracy.

- Follow the manufacturer’s guidelines and recommended procedures for proper flushing.

Step no.2 - Flush Both Impulse Lines

- Next, flush both the high-pressure (H.P.) and low-pressure (L.P.) impulse lines connected to the transmitter.

- This step ensures that there are no blockages or obstructions that could impact the pressure measurement and subsequent flow indication. Verify that the impulse lines are clean and free from any restrictions.

Step no.3 - Adjust the Zero

- Check the zero setting of the transmitter and adjust it if necessary.

- Use equalization techniques to ensure that the zero reading is accurate.

- By equalizing the pressures on both sides of the transmitter(by opening the manifold equalizing valve), any potential offset in the measurement can be eliminated, restoring the transmitter to its correct reference point.

Step no.4 - Check the L.P. Side for Choke

- If adjusting the zero does not resolve the issue, focus on the L.P. side of the transmitter.

- Examine the L.P. impulse line for any chokes, restrictions, or blockages that may be hindering the pressure measurement.

- Clear any obstructions found and recheck the flow indication.

Step no.5 - Check for Leaks on the L.P. Side

- Thoroughly inspect the L.P. side of the transmitter and associated connections for any leaks.

- Even small leaks can impact the pressure measurement and result in inaccurately high flow indications. Repair any identified leaks and verify the impact on the flow indication.

Step no.6 - Calibrate the Transmitter

- If the above steps do not resolve the issue, consider calibrating the transmitter.

- Calibration involves comparing the transmitter’s output to a known reference or standard to ensure accurate measurements.

- Follow the manufacturer’s recommended calibration procedures and make any necessary adjustments during the calibration process.

Step no.7 - Documentation

- Throughout the checking process, it is important to document each step taken, observations made, and any changes performed.

- This documentation serves as a reference for future troubleshooting, maintenance activities, and audits.

Step no.8 - Completion

- If the flow indication problem persists after calibration, it is best to discuss it with experts in the field, instrumentation professionals, or the manufacturer’s technical support about servicing or replacing the calibrated DP transmitter.

- They can offer more advice, sophisticated diagnostic techniques, or recommend additional corrective activities to remedy the issue.

- Remember that troubleshooting complex systems frequently necessitates a thorough and systematic approach, with an emphasis on safety and respect to appropriate procedures and laws.