What is a transformer

The transformer is a device that is used to transfer electric power from one voltage to another voltage without changing the frequency by electromagnetic induction. Transformers can increase or decrease the voltage with a corresponding increase or decrease of current. In a power system transformer is the main part so if any failure in the transformer can extremely affect the whole function of the power system. Transformer plays an important role to create an electrified world. Power distribution is achieved in many places is with the help of transformers. The very concept of AC electricity won’t work without them, so in a world, without transformers, many of our common devices will be useless.

What is a furnace transformer

A furnace is a device which is used for heating, and the industrial furnace is used for many purposes, such as the extraction of metal from ore, or in oil refineries and other chemical plants. There is much qualitative range of furnace transformer that is manufactured and designed using cutting edge technology. Mostly furnace transformers are used in steel plants and aluminum industries. These come with various distinguishing factors that provide them superior functioning rates and durability. These transformers are available with automatic on and off cooling facilities in various sizes with on-load tap changers. Furnace transformers are used to convert mains voltage to power electronics in the electrical appliances. These transformers are widely available in different power ratings. Furnace transformer will adapt electrical energy to the requirements of the electrical furnaces.

What is the difference between electric arc furnace and induction furnace

Induction furnace is used for both ferrous and non-ferrous melting applications, induction furnace exhibits good melt agitation, relatively easy fume control and rapid heat-up. It is not as dusty as electric arc melting, it only produces 20 percent as much effluent dust. In general induction furnace will create less pollution when compared to the electric arc furnace.

What are the types of furnace transformer

What is arc furnace transformer

In many industrial applications arc furnace is used for example in the steel industry they are used to smelting scrap iron and for refining steel. They are also used for other applications such as smelting glass and ceramics, manufacturing and refining of many materials. Electric arc furnace can be either AC or DC and the power ratings of these transformers are 20 – 200MVA. Reactors are used to smoothen the fluctuations, either in the same tank or in a separate unit.

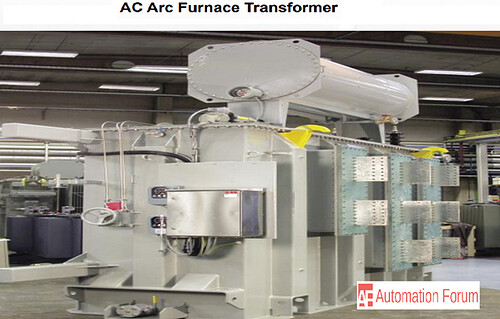

AC arc Furnace transformer

Ac arc furnace transformer can be used for long arc and short arc operations. These types of electric arc furnace transformers are used for many different furnace processes and applications. These types of transformers are used for steel furnaces, ladle furnaces and smelting of other materials steel arc furnace does its operation under severe conditions. With regard to frequent over-voltages and over-currents generated by the short circuits in the furnace and the operation of the HV circuit breaker. They have cyclic loading but in case of other applications loading is continuous at high utilization.

DC arc furnace

DC furnace transformer needs to withstand the stresses of furnace operation and it also needs to withstand other stresses which are related to the rectifier operation. This transformer behaves as a rectifier transformer for furnace operation. The HV side needs to be protected from frequent switching over-voltages. Most large DC furnaces are made for steel production. The use of the thyristor rectifier for the conversion to DC normally reduces the requirement for on-load voltage regulation of the furnace transformer. The step voltage is larger than the AC voltage, and a no-load tap changer is adequate in many applications.